by ruijie

An In-Depth Exploration of the Essential Components in a Fiber Laser Cutting Machine

A complete fiber laser cutting machine typically consists of several essential components, each playing a crucial role in the metal cutting process. Here are the Metal Fiber Laser Cutter main components:

MAIN STRUCTURE

1,Laser Machine Bed/Table:

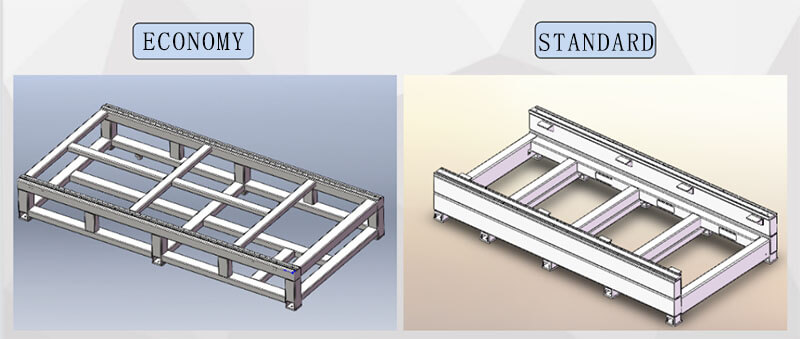

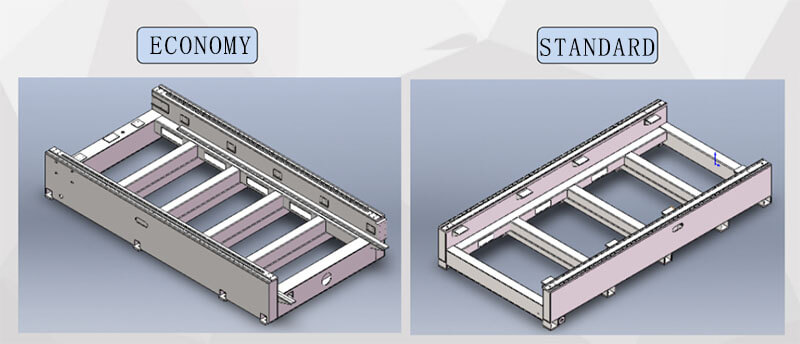

The bed or table provides a stable platform for the workpiece. It may have different configurations, such as a fixed bed or a gantry-style design. We have two beds for you to choose from,Square Tube Welded Bed Frame and Plate Welded Bed Frame.

Square Tube Welded Bed Frame

-

-

Plate Welded Bed Frame

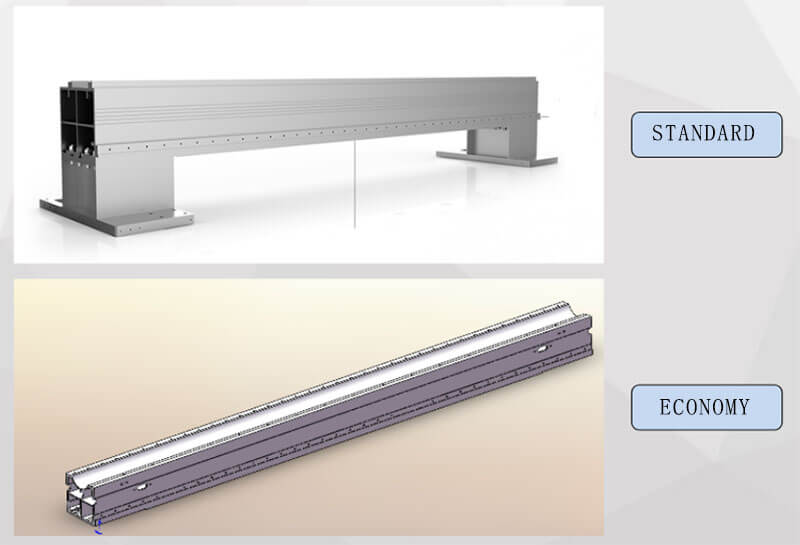

2, Fiber Laser Cutting Machine Crossbeam:

The crossbeam of a fiber laser cutting machine refers to its horizontal support structure. It is typically a transverse beam spanning the

entire cutting area, pr-oviding support for the fiber laser cutting head and other essential components.

The crossbeam is usually constructed using high-strength metal materials, such as steel or aluminum alloys.

Aluminum Profile Crossbeam

Manganese Steel Crossbeam

Cast Aluminum Crossbeam

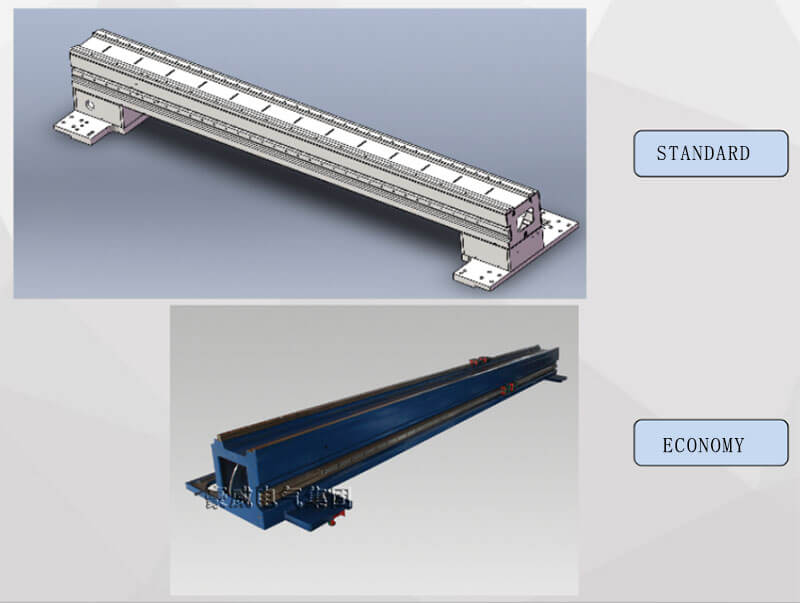

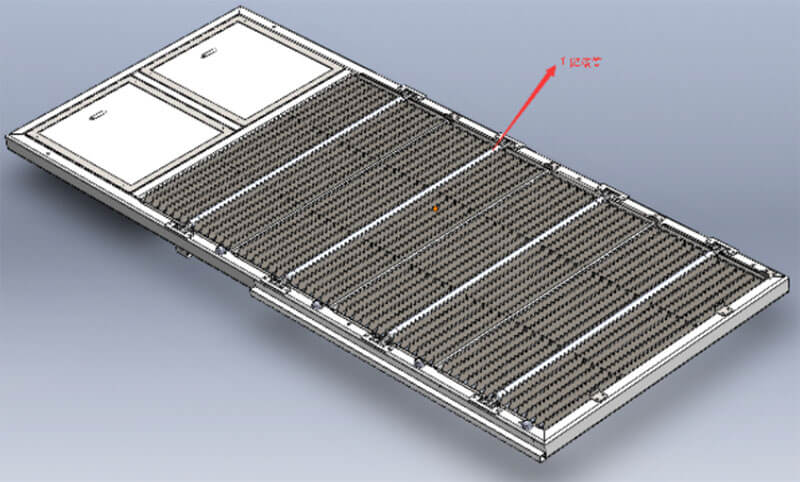

3, Tabletop Frame:

The tabletop frame of a fiber laser cutting machine refers to the supporting structure in the cutting area that holds the workpiece (the

aterial to be cut). The tabletop frame is typically a flat structure, which can be either fixed or movable, depending on the design and

functionality of the cutting machine.

The tabletop frame of a fiber laser cutting machine must have sufficient stability and robustness to ensure that the workpiece does not

experience unexpectedmovement or deformation during the cutting process. A high-quality tabletop frame helps maintain cutting precision and repeatability,

leading to higher-quality cutting results.

CONTROL SYSTEM

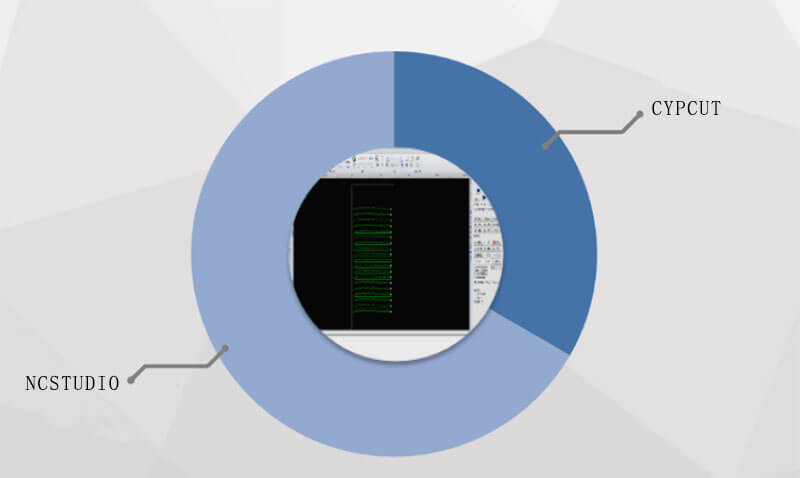

The controller is the core of a fiber laser cutting machine. Main Using CypCut System and NCSTUDIO System.

1, CypCut System:

The CypCut system is a computerized control system utilized in fiber laser cutting machines. It can receive and interpret numerical

instructions from cutting software and convert them into electrical signals to control the movement of the laser cutting head and various

motion axes. The CypCut system is responsible for precise control of the cutting path and coordination of movements.

2, NCSTUDIO System:

The NCSTUDIO is another computerized control system commonly used in fiber laser cutting machines. It functions similarly to the CypCut

system, receiving numerical instructions from cutting software and translating them into electrical signals to control the laser cutting head

and motion axes. The Weihong system ensures accurate control of the cutting path and facilitates smooth coordination of movements.

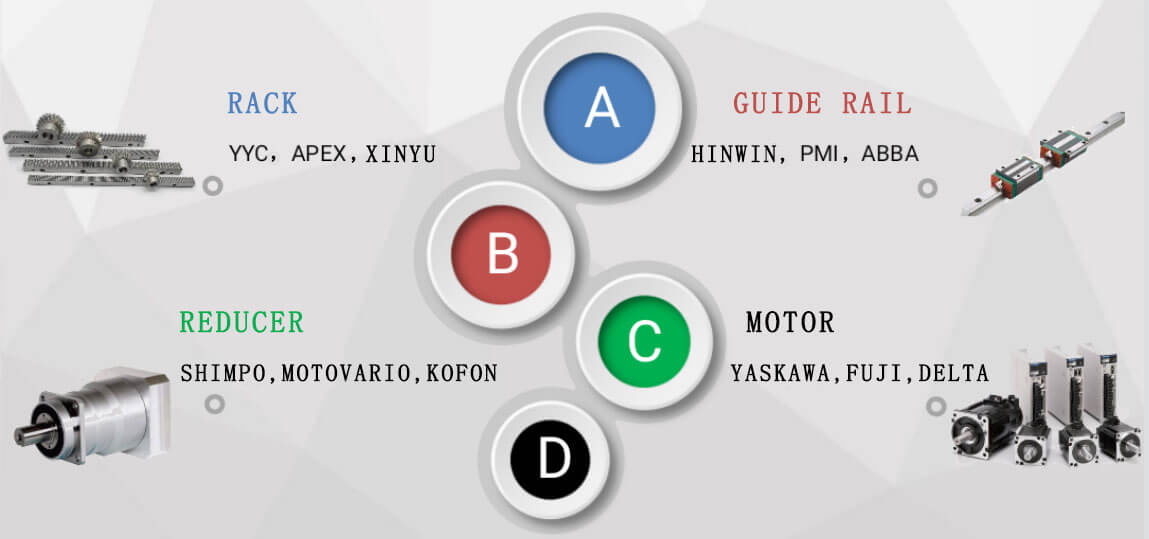

TRANSMISSION SYSTEM

The transmission system of a fiber laser cutting machine is used to achieve the movement of the laser cutting head along the X-axis,

Y-axis, and Z-axis. The transmission system typically consists of the following main components:

1, Servo Motors: Servo motors are a crucial part of the transmission system. They receive signals from the controller and drive the

transmission devices to achieve precise positioning and movement of the laser cutting head along different axes.

2, Transmission Devices: Transmission devices convert the rotational motion of the servo motors into linear motion of the laser cutting

head along each axis. Common transmission devices include ball screws, gear transmissions, and synchronous belts.

3, Guide Rails: Guide rails are linear guiding devices on the laser cutting machine that support and guide the movement of the laser

cutting head along the X-axis, Y-axis, and Z-axis. High-precision linear guide rails are commonly used to ensure stability and accuracy

during the movement of the laser cutting head.

4, Sensors: Sensors are used to detect the position and motion status of the laser cutting head, and they provide feedback to the control

system for closedloop control and precise position adjustments.

The performance of the transmission system significantly influences the precision, speed, and stability of the fiber laser cutting machine.

A high-quality tran-smission system ensures that the laser cutting head maintains accurate positioning and movement during the cutting

process, leading to high-quality cutting results.

LASER SOURCE AND LASER HEAD

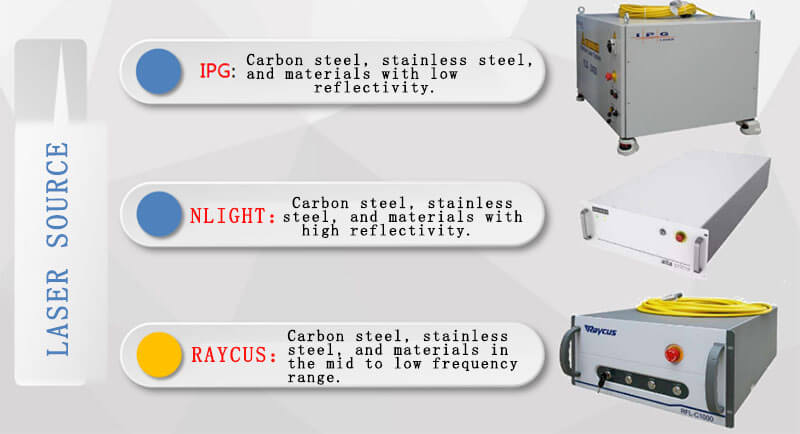

1, Laser Source:

For fiber laser cutting machine, the laser source is a crucial component responsible for generating the laser beam. The laser source

utilizes optical fibers as the laser medium and activates the laser medium to produce a high-energy laser beam. This laser beam is transmitted

through the optical fiber to the cutting head and then focused onto the workpiece using lenses, enabling precise cutting.

Different fiber laser cutting machines may utilize various types and power levels of laser sources, depending on the specific cutting requirements

and the type of materials being processed. Our company currently primarily uses three types of laser sources: IPG, nLight, and Raycus.

IPG Laser Advantages:

High Efficiency: IPG lasers utilize fiber laser technology with high electro-optical conversion efficiency, resulting in energy-saving and high efficiency.

Excellent Beam Quality: IPG lasers produce laser beams with outstanding beam quality, high beam quality, suitable for high-precision cutting and

welding applications.

High Stability: IPG laser output power and beam stability are high, making it suitable for long-term operations and frequent switching.

Long Lifespan: IPG lasers employ advanced fiber technology and design, leading to a longer lifespan and higher reliability.

nLight Laser Advantages:

High Power Semiconductor Lasers: nLight primarily focuses on high-power semiconductor lasers, suitable for applications requiring high-power output.

Good Beam Quality: nLight lasers exhibit good beam quality, suitable for various laser material processing and laser illumination applications.

Versatility: nLight lasers find wide applications in industrial material processing, laser illumination, communications, and medical fields.

Raycus Laser Advantages:

Multiple Power Options: Raycus lasers provide a range of power levels, suitable for diverse application needs.

Stability and Reliability: Raycus lasers offer stable output with good reliability and cost-effectiveness.

Cost-Effective: Raycus lasers offer a reasonable balance between performance and price, making them suitable for cost-conscious applications.

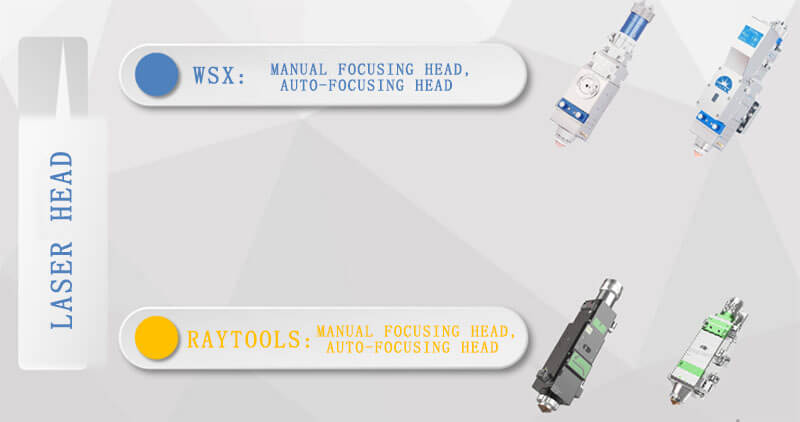

2,Laser Head:

The laser head is one of the most crucial components in a fiber laser cutting machine. It is responsible for focusing the laser beam onto

the workpiece to facilitate cutting and processing. The laser head of a fiber laser cutting machine typically consists of the following main parts:

Lens: The laser head contains a lens used to focus the laser beam into a small and dense spot. The quality and focal length of the lens have a

significant impact on cutting quality and efficiency.

Nozzle/Protective Mirror: The laser head is often equipped with a nozzle or protective mirror to shield the lens from splatter and contamination

generated during the cutting process.

Focus System: The laser head is equipped with a focus system that allows adjusting the distance between the lens and the workpiece to

accommodate the cutting requirements of different thicknesses and materials.

Cooling System: The laser head usually requires cooling to maintain normal operating temperatures during high-power laser cutting.

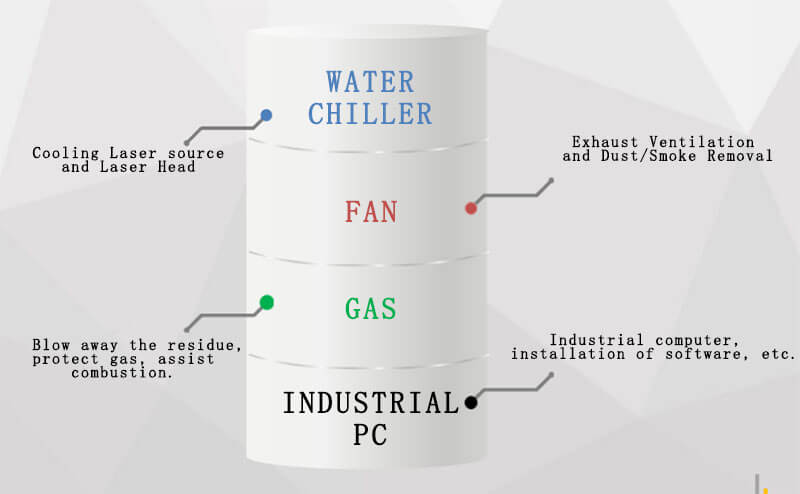

AUXILIARY SYSTEMS

The auxiliary systems of a fiber laser cutting machine are a series of additional equipment and functionalities designed to improve cutting efficiency,

facilitate operation, and ensure cutting quality.

The above provides a rough overview of the components of a fiber laser cutting machine. After reading this article, you should now have a good

grasp of the basics of fiber laser cutting machines. If you still have questions about choosing the right power for your fiber laser cutting machine,

you can refer to my this article (Customized Cutting Solutions: Matching Metal Materials with Different Power Fiber Laser Cutting Machines),

which offers a comprehensive explanation of selecting laser power for different cutting materials. For any other queries, feel free to reach out to us

via email sales@ruijielaser.com or our online customer service. We have 24/7 pre-sales and after-sales support staff ready to assist you.